OILFIELD CHEMICAL PRODUCTS

Delivering Top-Quality Friction Reducers, POP Lubricants, Biocides, and Xanthan Gum for Enhanced Oilfield Performance

THE OIL & GAS

EXPLORATION & PRODUCTION PROCESS

EXPLORATION

During exploration, geologists and geophysicists survey potential oil and gas reservoirs. As drilling commences, friction reducers are applied to the drilling fluid. These friction reducers minimize drag and resistance in the wellbore, ensuring smooth drilling operations and efficient penetration through the subsurface formations. This critical application allows exploration teams to reach target depths effectively while reducing operational time and costs.

DRILLING

Drilling operations involve the insertion and extraction of drill pipes in the wellbore. In this stage, POP lubricants reduce friction between the lines, making assembling and disassembling the drillstring much smoother. POP lubricants mitigate the risk of equipment damage and increase the efficiency of drilling operations by minimizing pipe-on-pipe friction.

WELL STIMULATION

In well stimulation, friction reducers and Xanthan Gum come into play during hydraulic fracturing operations. Friction reducers aid in reducing the friction between the fracturing fluid and the wellbore walls, facilitating efficient pumping and ensuring that the fluid reaches greater distances within the well. Meanwhile, Xanthan Gum acts as a viscosifier and stabilizer, improving proppant transport and providing successful fracture stimulation.

PRODUCTION

Once the well stimulation and production begin, biocides control and mitigate microbial-induced corrosion in the produced fluids. By preventing harmful microbial growth, biocides safeguard the integrity of pipelines, flowlines, and equipment, extending their lifespan and minimizing the risk of costly corrosion-related issues.

ADVANTAGES OF ASPEN CHEMICAL SOLUTIONS

Proven Track Record

With over 30 years of experience in polymer flocculation and chemical solutions, Aspen Chemicals has a proven track record of delivering results in the oil and gas industry. Our clients rely on our expertise and trust in our chemical products to meet their operational goals.

Enhanced Operational Efficiency

Aspen Chemicals' advanced friction reducers, POP lubricants, biocides, and Xanthan Gum are meticulously formulated to optimize oilfield operations at every stage. By reducing friction during drilling and fracking, our chemical solutions improve pumping efficiency, reduce operational time, and minimize equipment wear and tear.

Increased Well Performance

Our specialized chemical solutions, such as Xanthan Gum, act as effective viscosifiers, ensuring the proper suspension of solids and proppants during well stimulation. This enhances proppant transport and fracture conductivity, improving well performance and higher oil and gas production rates.

Versatility & Adaptability

Xanthan Gum, in particular, offers versatility and adaptability in various oilfield applications. Its exceptional properties, from thickening and suspending drilling fluids to enhancing oil recovery rates, make it a valuable asset in challenging environments, including high-salt areas.

Expert Technical Support

Partnering with Aspen Chemicals provides access to expert technical support from our experienced team of specialists. We collaborate closely with clients to recommend the most suitable chemical formulations, dosage levels, and application techniques, ensuring seamless integration of our products into their processes.

Environmental Compliance

Aspen Chemicals' biocides are vital in controlling microbial-induced corrosion, safeguarding pipelines, and minimizing environmental impact. Working with our biocides ensures adherence to environmental regulations and enhances the integrity and longevity of oilfield infrastructure.

APPLICATIONS

POP Lubricants (Pipe-on-Pipe Lubricants)

INDUSTRY SPECIFIC SOLUTIONS

SAFETY & COMPLIANCE

THE ASPEN CHEMICALS DIFFERENCE

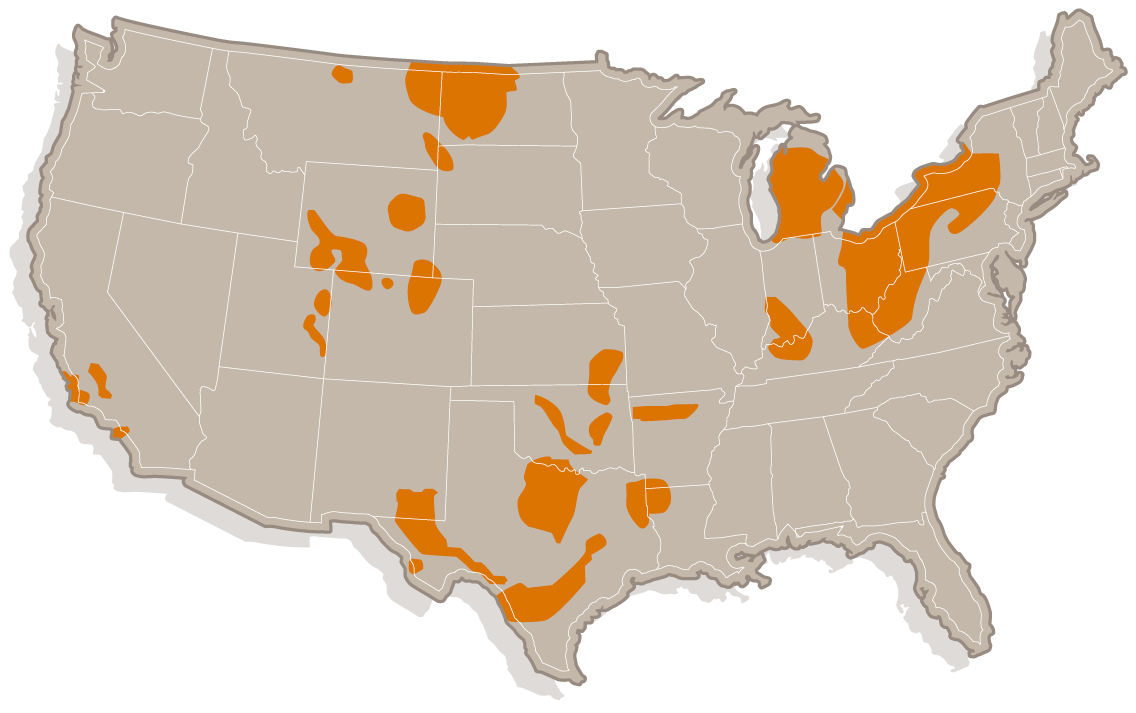

OUR REACH